A team in Colorado is accurately estimating coal stockpile volumetrics with drones.

Arch Coal is the second-largest domestic producer of metallurgical and thermal coal in America, with 96 million tons of coal sold in 2016. In total, Arch represents more than 13% of America’s coal supply from their complexes in Colorado, Illinois, Kentucky, West Virginia, Wyoming, and Virginia. Of course, Arch is interested in accurately quantifying their coal stockpile inventory on a regular basis.

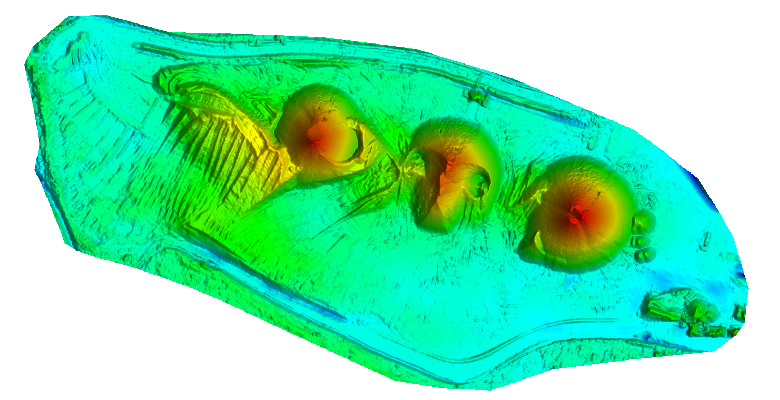

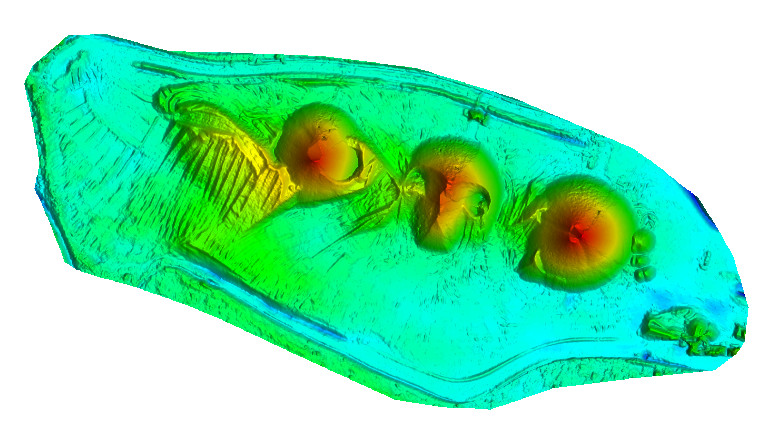

Figure 1: One of Arch Coal’s stockpiles with three coal stack tubes and a conveyor system.

Arch Coal’s West Elk mine in Somerset, Colorado is a long wall mine where the mined coal is conveyed out of the mountain and deposited on the terrain surface. We at DroneMapper have been working with Arch Coal at that location for the past five years in developing an affordable workflow to accurately estimate coal stockpile volumetrics using drone imagery collection, photogrammetric processing, and GIS tools.

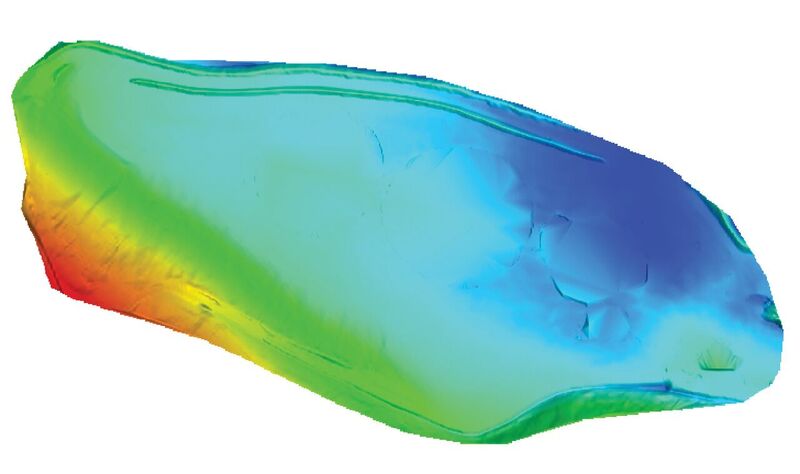

Figure 2: The geo-referenced base ground surface depicting an empty basin.

The resulting workflow could lead to a significant cost savings by establishing accurate volumetrics with low latency compared with traditional manned aircraft operations. Further, more frequent drone-acquired volume estimates can be used to check calibration of the real-time conveyor weight-scale measurements to assure consistent calibration of mechanical systems.

Figure 1 illustrates one of the stockpiles with three coal stack tubes (center right) with a conveyor system. Ground control targets are used for every imagery collection to precisely align the imaged stockpile surface with the bare ground reference surface.

Figure 2 shows the geo-referenced bare ground surface depicting zero volume (an empty basin). This surface was precisely constructed using the control points that surround it. The colors represent the surface elevations, with red being the highest elevation and blue the lowest. Note that the two ridges at the bottom of the surface illustration correspond to the ridge features seen in the stockpile image.

Imagery Collection and Processing

Arch Coal collected imagery using a DJI Phantom 3 Advanced quadcopter flying at approximately 300-400 feet above the ground/stockpile surface. At this elevation, the Phantom 3 will produce approximately a 2-inch pixel image of the ground.

A traditional 80% overlap (forward and side) grid was used for nadir imagery collection. The nadir imagery was augmented with an orbital oblique imagery collection to obtain stockpile surface data obscured by the conveyor system above the piles.

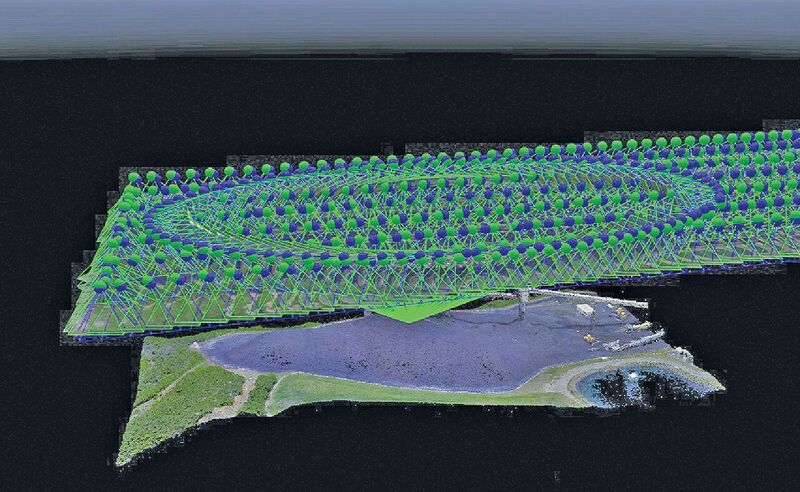

Figure 3: The camera pose during the collection for both nadir and oblique shots.

Figure 3 illustrates the camera pose during the collection for both the nadir and oblique shots. DroneMapper has shown that the use of nadir and obliques provides for a higher-quality digital elevation model (DEM) with less noise and artifacts than nadir alone.

Once collection was completed, the images were sent to DroneMapper for control pre-processing and full photogrammetric processing to generate the DEM and GIS manipulation for volumetric estimation.

We use our Windows-based Remote Expert software for 2D control file generation and photogrammetry. The 2D control file is generated using a tool that selects the number of images at a certain radial distance from the control by comparing the image geo-tags with the GPS coordinates of the control points. In this manner, an operator doesn’t have to review every image for every control point in the scene, saving time.

Each image identified with a control point is then zoomed in so we can select the pixel in the center of the control target.

Figure 4: Typical aerial target control points used in image processing.

Figure 4 shows typical aerial target control points (three-leg targets) used in image processing.

Remote Expert uses this 2D file and a 3D file (defining control x,y,z coordinates) along with the imagery for DEM processing.

Figure 5: The resultant DEM

Figure 5 shows the resultant DEM. Quality verification is performed by comparing the control elevations with the elevations of those points on the DEM to establish the root mean square error (RMSE) for the control.

We then use the elevation RMSE to estimate the elevation accuracy, which directly contributes to volumetric estimate uncertainty. Typically, we see elevation errors of less than 1 pixel, or less than 2 inches for this case.

Volumetrics Estimate

DroneMapper employs Global Mapper, from Blue Marble Geographics, for GIS post-processing. The two surfaces, DEM and bare ground, are terrain-combined (subtracted from each other) to yield a volume model of the stockpile. The image looks identical to the DEM; however, the base of the model is at 0 meters elevation.

Global Mapper then quickly computes the volume of the entire pile or sub-piles within the overall stockpile by digitizing the selected pile of interest for computation.

Data Use

Arch Coal’s West Elk facility can now quickly and affordably use drone and imagery-processing technologies to establish a comparative volumetric estimate at the times of their choice, weather permitting. This data may be used for calibrating or augmenting other weight- or volume-measurement equipment being used at the facility.

The data also provides visibility on ground operations within the stockpile to assess inventories of coal in various processing stages for overall accurate inventory situational awareness.

To read more from this print issue, click on the cover below.