A mapping and design firm in the Pacific Northwest implements UAS in diverse urban and rural environments.

Matt Kumpula, PLS, is DEA’s mobile mapping and sUAS flight operations manager.

Editor’s Note: Integration (or not) of UAS by geospatial firms runs the gamut from outright dismissal of the technology, to firms taking a wait-and-see stance, to companies subcontracting out UAS services. Then there are those, like the mapping and design firm of David Evans and Associates, that have adopted and integrated UAS at an organic level.

David Evans and Associates (DEA), founded in 1976 in Portland, Oregon, employs more than 1,000 people in nine states in the fields of energy, land development, transportation, water and environment, surveying, and geomatics and marine services.

We talked with Matthew T. Kumpula, PLS, mobile mapping and sUAS flight operations manager, about the firm’s approach to integrating UAS technology into its operations. (Matt’s also a winner of xyHt’s Next Big Thing essay contest—check it out!)

DEA’s remote pilot Ryan Reedy (left) and structural engineer/remote pilot Eric Ferluga (right) perform a structural inspection of a railway elevated guideway using HD video goggles. Not pictured is author Matt Kumpula who is ensuring that the flight is safe.

ADOPTION DRIVERS

We saw that UAS was something that would bring value to our clients and projects. UAS has actually been around a long time already, and it’s becoming an accessible tool. I think that’s where you can’t look away any longer from how far-reaching it’s becoming. UAS is not just a geospatial tool; it’s something that all professionals within the consulting realm have access to.

Larger UAS can handle the optical zoom camera payloads with room to spare

I think that was the driver for us to look at UAS on an organic level. We saw this would enhance the work our transportation engineers, structural engineers, rail engineers, civil engineers, electrical engineers, environmental scientists, marine scientists, planners, public involvement folks, land development folks, and, naturally, our geospatial and survey staff have been doing over the last 40 years.

Our professionals require information and perspectives that are often hard or impossible to achieve cost-effectively. Often, unless you’re a subject-matter expert, you’re unable to be successful acquiring actionable information with a UAS regardless of how great a remote pilot you are, due to not understanding what you’re trying to accomplish. These were the gaps we understood our professionals wanted to bridge, and there are many bridges.

This bridge has been shut down to vehicle traffic, and DEA’s sUAS Center of Excellence and Bridge & Structures Group uses it for bridge-inspection training. It’s the last bridge on the Puyallup River to the Puget Sound.

The FAA offers commercial operation certification under 14 CFR Part 107; however this addresses only knowledge and doesn’t have a proficiency or performance-based test with flight of the UAS itself. This is left to the commercial operation, so for us, this meant creating internal training to ensure proficiency of our pilots for safe operations and alignment with best-risk management practices. This had to carry across our fleet of 12 registered aircraft to ensure our remote pilots were proficient which each UAS and the limitations thereof.

I think we understood how disruptive this was initially; however, we didn’t anticipate the X factor, which was how many people came out of the woodwork internally from all varying nooks and crannies of our organization and said, “I want to get involved in this—I want to have access to this tool—how do I get involved?”

When you have that response to a geospatial lead technology, I think it’s a strong driver for a company to say, “We hear that, we see that, we need to get behind this and move this forward.”

Kumpula (left) demonstrates an inspection maneuver for a remote pilot in training with a UAS near overhead utilities along the shut-down bridge.

INSPECTION

We actually just completed an inspection cycle for a large transit agency up here in the Northwest that has a number of elevated guideway segments for their rail system.

We utilized UAS to help them in the structural inspection process to mitigate some of the impacts to the ridership on their railway, which ultimately would have affected their revenue. The project was about 4.2 miles of elevated guideway, and we provided added detailed inspection with the UAS to our traditional bridge and rail inspection methods.

This project demonstrated a case where proper training of our remote pilots and detailed preparation with emulation of a challenging site condition yielded a successful result on site for the client. Ultimately, the focus for implementing the technology was to remove the human element from the railway and the bridge structure, which in itself is a risk reduction.

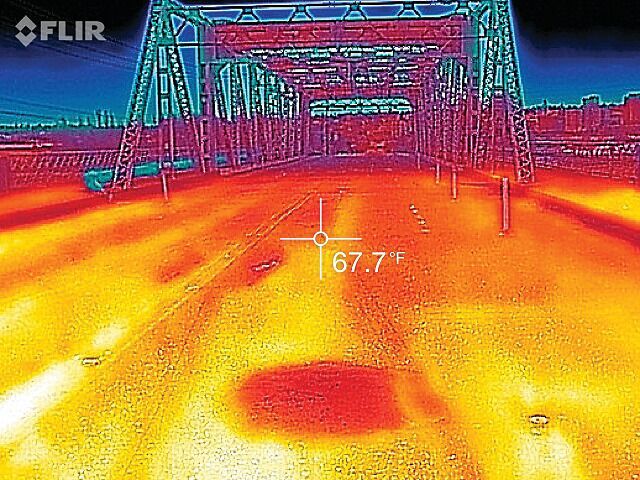

Applications of thermography are applied to the concrete sections of the bridge.

The imagery acquired by our inspection team is a highly intuitive spatial product and, when put before the eyes of the next inspector, becomes an even more powerful documentation method.

From our overall UAS business uses, bridge inspection is ob- viously a large driver, but it’s not the only inspection focus. There is also other infrastructure inspection, such as the utility infrastructure component that’s also a large focus for us. This requires going beyond just the RGB sensors, the cameras, the high resolution, the zoomable optics, the glass advantage, if you will.

It’s really reaching into the thermal sensors, the micro bolometers, the thermography element. The use of multiple sensors allows us to record and disseminate information about the infrastructure for maintenance and repair.

We are disseminating the data from those sensors into something meaningful based on the client-driven specifications, be it finding deficiencies or operational tolerance validation. This is a growing area for us.

We do have the occasional rooftop and building inspection case that comes up, as well. That seems to be something that’s handled more by the building contractors themselves. We don’t typically get a lot of those requests at this point; many contractors seem to self-perform this work.

Remote pilots prepare UAS on the rooftop landing pad, or “Drone Port,” for test flights prior to a project application.

CHALLENGES OF THE PACIFIC NORTHWEST

Typically, it’s going to be the vertical elements in the terrain and the moisture. We also have a lot of unique infrastructure that had to be built into our mountainous and contoured terrain. There are several water bodies that had to be spanned with structures and infrastructure. Then, that infrastructure needed to be mapped, built, inspected a number of times, and repeated.

Industry requires technologies that can quickly and safely access the built and natural world economically to help us gain a more comprehensive picture. That’s something that’s always been lacking, and UAS is the first thing to really start to fill that void. With challenging environments comes a need for innovation. I think in the Northwest you can see the impact of UAS being realized in a way more meaningful than in other areas of the country.

One of the other challenges is the safety issue. I think that’s been the initial adoption and implementation hesitancy in the Northwest. For example, here in the state of Washington, there is a continental divide and a coast that creates a narrow and densely populated strip in which most of the population lives west of the mountains and east of the Pacific Ocean; therefore, most of the infrastructure is in a very compressed area.

The use of multiple sensors allows us to record and disseminate information about the infrastructure for maintenance and repair.

With that comes a lot of private property, private property rights, a lot of very dense development, tall fir trees, steep terrain, and challenges for integrating UAS in a safe manner in and around the infrastructure and the people. In order to be successful in operating UAS here, you have to know your regulatory environment, your application, your sensors and payload, and your operational procedures to understand what is safe, what is achievable, and when technology is appropriate or not appropriate.

All these things have added to the challenges of integrating that UAS technology into the Northwest. We really are exclusively a true VTOL platform market, unless you are in agriculture.

Also, the Northwest requires more robust IP-63 rated aircraft for year-round operations, such as those that are “military grade” or more robust in construction with design considerations for the moisture in the environment. We have a lot of infrastructure that crosses over the mountains, as well; therefore, we have cold temperature. And, finally, there is the coast, with high winds and rocky bluffed shoreline lined with fir trees.

I make this area of the country sound so great you’ll want to move here!

DEA’S CENTER OF EXCELLENCE AND DRONE PORT

The focus of our Center of Excellence for UAS is on the implementation of the technology across all of our business lines. This focus came from our established Geomatics Center of Excellence lead by vice president, Marcus Reedy, PLS.

We do have a rooftop landing pad, a “Drone Port” if you will. It’s one of the first that I know of in the western part of the U.S. It will show up on Google Earth here soon; it was designed to stand out. The design on the landing pad is our approved logo over a rudimentary quadcopter that was actually designed with a specific intent.The landing pad design itself is meant to help the optical flow imagery recognition and the computer vision process for precise and stable autonomous landing of sUAS.

The reason it’s on the rooftop is that we’re in an urban environment, again intentional. We’re actually in a downtown area, south of Seattle, in the city of Tacoma, which is a port city. We hold the on-calls and the major contracts with the city, county, the port, and the state for this particular area.

We also have a relationship with several building owners down here in the downtown area where we are able to navigate and fly over these different buildings (VLOS currently, BVLOS in the future), so we can execute navigation that we know as an aerial easement. We utilize visual observers to ensure that we can honor Part 107 currently as written and that we can cross the drone over the street.

We can execute urban missions for use-case work in our own infrastructure. We also have extensive old utility infrastructure: sub-stations and power infrastructure. We use some of that power infrastructure to test some of our thermography and camera inspection techniques.

BIGGER THAN YOU THINK

UAS is much bigger than just the survey and mapping here at DEA. The applications to in- spection, monitoring, site reconnaissance, volumetrics, historic preservation, 3D modeling, and site visualization enhance the solutions we’ve been delivering to our clients. Having the access, scalability, and skilled professionals to be developing these things as a private company is a bit of a challenge, and we find ourselves in a unique situation to be able to do that.

It’s important to understand where this technology is going. We see the demand from our own folks to public- and private-sector clients.

To read the rest of the articles in this print issue, click on the issue cover, below.