Drone? Ground? Helicopter?

For years now drones, UAVs, UASs or whatever you wish to call them have been the revolution that promises to change the way we live. Five+ years into the drone revolution we are seeing some change—but it has certainly been a slower progression than expected.

Linewise Aerial specializes in transmission line inspection and corridor mapping. Allow us to share our experience and offer some recommendations to those debating how to best complete their next project.

We are experts in infrared, corona, visual inspection, and lidar. With headquarters in Atlanta, GA and Calgary AB, clearly North America is our focus; however, we provide services to clients worldwide. Our team has been at this for over 25 years. We perform all inspection needs.

Platform Agnostic

Clients often ask us for a UAV or helicopter proposal to solve a business need. Our recommendation is for the project to define the acquisition technique, not the opposite. Items to consider are:

- Project size

- Project location

- Safety

- Deliverables

- Quality requirements

- Environment

- Landowner

We recommend a platform agnostic approach. We perform ground inspection, UAV inspection, and helicopter inspection. In reviewing each project it is generally clear which acquisition technique is the most effective method of acquisition to obtain the deliverables required.

Helicopters, UAV, and Ground Patrol

We’ve heard it all:“Helicopters are too expensive.” “Ground patrol is old school.” “UAVs are cheaper and faster.” Let’s look at each.

Ground Patrol

This traditional technique for powerline inspection is still the most common type of inspection of a network. It is safe, reliable, and often the right solution for circuits in high-population areas. When considering ground patrol, look at the amount of line to patrol and the timeframe you need to patrol. In rural transmission areas look at the environment; swamp, thick underbrush, and mountainous areas are examples where ground patrol is difficult.

Getting access to lines on private land can be slow and costly. Consider landowner consultation, environmental considerations such as rutting (access mats? low tire-pressure vehicles?) and transfer of noxious weeds (vehicle wash stations at property line?). Our recommendation is to have GPS on the crews for safety and for landowner inquires (gates left open, etc.).

As for deliverables, ground patrol is generally limited compared to UAV and helicopter. Common deliverables are bottom up geotagged pictures—infrared, corona and visual.

At a quick glance, ground patrol may look like the least-expensive acquisition technique; however, once the deliverables and all costs are considered, it is not always the most cost-efficient.

UAV Inspection

UAV inspection is the inspection technique every utility wants to talk about. It can capture excellent data quality and do so efficiently depending on the project size and location. We find UAV inspection to be best for small linear inspections in non-sensitive areas. As flight restrictions decrease and payload and power supply increase, we are excited to be involved and at the leading edge of UAV inspection.

While beyond-line-of-site permits are becoming more common, most UAV operators are impacted by line-of-sight regulations. Additionally, two-man crews are required to maintain line of sight. A common UAV setup would include one or two sensors depending on payload and power availability.

Similar to ground patrol, UAV can be quick to mobilize but is also impacted by the same issues as you need to get feet to the ROW. Difficult environment—swamp, underbrush, mountainous—as well as land owner considerations—consultation, rutting, noxious weeds—apply. If operating near roads, a traffic plan can also be required.

Deliverables for UAV include geotagged high-resolution video and images with ability to capture full 360-view of an asset looking from almost any angle. If performing inspection with multiple sensors (IR and UV), additional flights are required with the resulting videos not always looking at the same thing from the same angle.

Our experience is that the higher cost of UAV vs ground patrol can be offset with enhanced deliverables.

Helicopter Inspection

With far fewer flight restrictions than UAVs on payload and power supply, helicopters can operate airborne sensors that collect higher-quality data more efficiently. Compared to ground or UAV acquisition, helicopters with multiple sensors can acquire significantly more per day than UAV or ground—up to 20x. Helicopters can be limited in the areas they can fly however this can generally be mitigated with permits.

Multiple Sensors

We collect the following in one pass of the right of way:

- Infrared inspection

- Corona inspection

- HD ROW video

- High resolution oblique images

- Orthomosiac images

- Lidar

This solution combines seven sensors on a helicopter to acquire the best possible data. As all cameras have the same target, acquiring in one pass allows the data to be overlaid and analyzed.

Perception is that helicopters are expensive. When considering large linear projects, helicopter use is generally lower-cost with better deliverables. This is due to the combination of large amount of daily acquisition and lack of access costs as compared to ground patrol or UAV.

Infrared, Corona & Visual Inspection

Can you do infrared only? Corona only? With best intentions in mind, clients have different views on how to best inspect their network.

If we can agree that the purpose of these inspections is to identify all possible anomalies and confirm electrical integrity on a line, then why not both? In fact, why not both and visual inspection at the same time?

Infrared provides a non-contact, efficient means of identifying electrical anomalies which could result in failure. Corona uses an ultra-violet image sensor to detect partial discharge, corona, and arching.

It is our belief the three sensors—infrared, corona and HD-visual are complimentary. Each sees different anomalies—and often the same, providing additional information which can be used to classify the severity of each anomaly.

To accomplish this we inspect and overlay infrared and corona technologies for identification of anomalies that cannot be recognized by any other means. Our inspection is performed on all line hardware, conductor, shield wire/sky wire, insulators, splices, sleeves, spacers, dampers, grounding, OPGW etc. with anomalies classified and reported on a three-tier system.

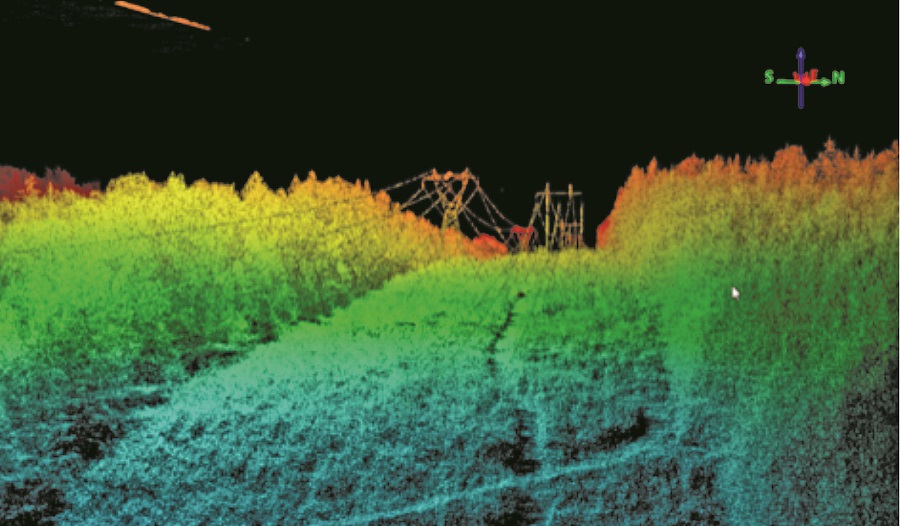

Example of a dense lidar point cloud collected over a transmission line in heavily vegetated terrain.

Lidar Inspection

Fifteen years ago, how much lidar inspection was performed? Much has changed since then. The cost is now a fraction of what it was with the data accuracy continuously improving. We have yet to meet a powerline owner that is not familiar with lidar.

Lidar is a proven tool for managing powerline networks. Most common uses are compliance, encroachment and modeling.

Over the years, lidar has evolved to a deliverable that multiple business units can use. Deliverables can be used for GIS data, as-builts, new-builds, change detection, encroachment, vegetation analysis, STR modeling, legal dept., topographic mapping, surface mapping, and any other modeling or mapping needed for the client.

Where Is the Industry Going?

In our experience there is no single method of acquisition that is best. While many variables impact the decision on best acquisition method, our rule of thumb is:

- Ground Patrol: Small projects, city environment, picture will suffice.

- UAV: Small to medium projects, rural area, video and pictures required (i.e. ROW vegetation)

- Helicopter: Large and medium projects, multiple sensors inspection, time is of the essence.

When it comes to inspection type, our recommendation for electrical integrity is to perform infrared, corona, and visual inspection. While each on its own has merit, the true picture is captured with all three. For vegetation and ROW inspection lidar is always best, however, when lidar is not in the budget, a high-definition geotagged video of the ROW can suffice.