Above: This image illustrates the transition from point clouds to modeled deliverables. These non-BIM solids were later used for com-putational fluid dynamics analysis to ensure proper airflow throughout the room.

Three ways you can derive value from point clouds past the pre-design phase.

By Daniel Chapek

Reality capture is a powerful way to digitize the physical world and to generate a comprehensive understanding of existing conditions. Teams can use multiple technologies for reality capture; for this article we’ll focus on laser scanning.

Laser scanners capture a collection of individual points, referred to as a point cloud. Many architecture and design firms gather information about existing conditions at a building site with a laser scanner and use that data as the basis of their designs. It’s important to recognize that point clouds are also incredibly useful well past the pre-design phase of a project.

In our experience, there are three main ways firms derive value from point clouds past the pre-design stage.

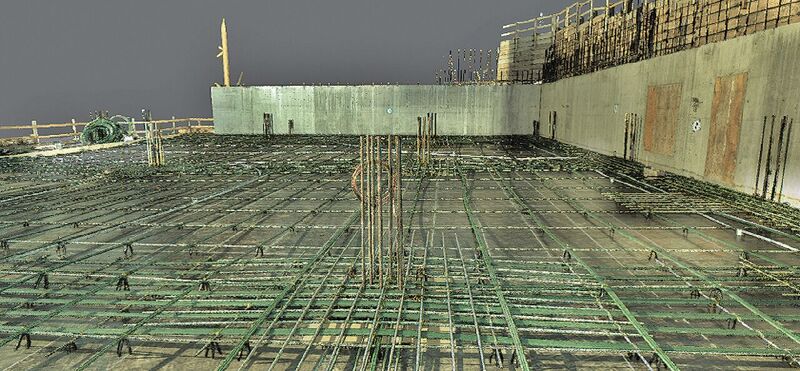

This point cloud provides clear doc-umentation on the steel reinforcement and post-tensioning cables minutes before they were covered in concrete.

In Their Native Format

After teams generate a point cloud, they can use it “as is,” without any additional intelligence added to it. Visualization is one of the best ways to realize value from point clouds in their native format. Owners appreciate visualizations, because they are powerful tools for marketing building space to potential customers. Visualizations offer a contextual understanding of the space, as well as basic measurements.

Visualizations can also support augmented reality for interactive media. For example, one of our architecture and construction customers works with a museum and scanned a retired Navy aircraft carrier. From this data, they will create a digital model that will be leveraged in the museum’s interactive multimedia guide, showing animations of how sailors would have worked on the ship during wartime.

Another application for point clouds during the construction phase of a project is as a clash-detection tool. Once construction begins, teams iteratively laser scan the project site. After each scan, the team can compare the resulting point cloud with the design model. This identifies any areas where the current as-built environment is different from what was initially specified in the design.

In some cases, those differences have no project impact, but in others they can flag upcoming problems. The point-cloud information allows teams to take action early and head off issues before they become crises.

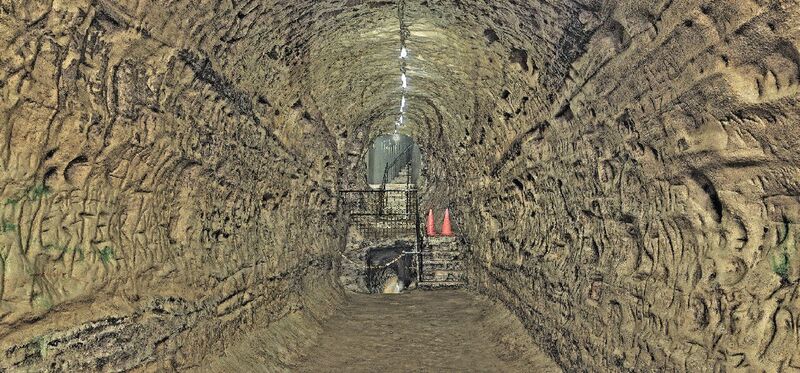

This visualization of a simple point cloud serves as document- ation of the existing condition of a cave–after construction crews added lighting and other safety aspects to open this cave for tourism–proving the preservation of the historical site.

Modeled into Solid Geometry Objects

In projects that don’t have building information modeling (BIM) requirements, designers may use point-cloud data to create 3D solids that represent piping and structural steel. Teams use these solid geometry objects for measuring, connection tie points, and clash detection.

Another example of modeling point cloud data into 3D solids is in manufacturing environments where factory equipment is massive. If machinery must be moved to support new plant layouts, facilities managers want to make sure that it will be moved only once. Point clouds are well suited to help with this type of space planning.

With a laser scanner, teams can scan a piece of machinery and transform the point cloud data into a solid geometry object. They can then place the digitized piece of machinery into a 3D model of the new space to ensure that it will fit. This gives facilities managers peace of mind before the company spends time, money, and effort to move the equipment.

This iterative approach to data collection provides a richer BIM deliverable than simply scanning the finished project site.

Point clouds are also useful for historical preservation initiatives. Teams can use laser-scanned data to create solid geometry representations of architectural details like carvings, decorative plaster, and more. They can send that information to a 3D printer to create accurate replicas.

Turned into a BIM Deliverable

As noted earlier, during construction, teams may decide to laser scan the site periodically over the course of the project. They can incorporate the information from these point clouds into a BIM deliverable. This iterative approach to data collection provides a richer BIM deliverable than simply scanning the finished project site because it enables teams to capture important information about the building infrastructure, such as beams and plumbing, that is not visible once the project is complete.

Once teams incorporate that data into the final BIM deliverable, the result is a powerful tool that building owners can pass on to their facilities management teams. With the BIM deliverable, facilities managers can locate building elements that need maintenance, to answer tenant questions, and more.

Although organizations need some form of reality-capture hardware to create point clouds, it’s important to remember that they also need backend software tools to deliver successful results.

In addition, point clouds often contain large volumes of data. To share them effectively with internal and external partners, organizations must have data-management tools.

We’ve seen many ways to create value with point clouds past the pre-design stage of projects. Maybe it’s time for your firm to think about ways to use reality capture to do your work better. As you explore different alternatives, don’t let your preconceived ideas about technology constrain you. The sky’s the limit.