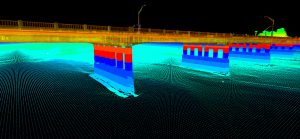

Above: The survey included collecting bathymetric data on the river bottom and bridge substructure with multibeam sonar as well as capturing above- and below-waterline mobile mapping data with the Leica Pegasus: Two mobile sensor platform.

Two well-paired engineering firms used high-accuracy mobile mapping to combine bathymetry and lidar data for a fast-turnaround topographic survey of the Clearwater Memorial Bridge in Idaho.

As it arrives at the state line separating Washington from Idaho, the Snake River forks, one tine flowing to the south as the Snake along the border, the other heading due east as the beginning of the Clearwater. Anyone traveling east on a boat would quickly encounter the Clearwater Memorial Bridge, which is the only easy way to get across the Clearwater should you want to travel between Lewiston and North Lewiston.

Roughly 750-feet long and dedicated to veterans of WWII, the bridge opened in the spring of 1951 with a ceremony led by Idaho governor C.A. Robins, after two years of construction at a cost of $1 million.

But the shine has worn off. The bridge was designated “functionally obsolete” by the federal government more than a decade ago, largely because of the roads that feed it, which are no longer suited to the traffic the bridge handles daily.

In March of 2019, almost 70 years to the day after Lewiston mayor Leo Morgan turned over the first shovelful of dirt to begin construction, the Idaho Department of Transportation entrusted a pair of engineering companies with creating a full topographic survey of the bridge and surrounding area as part of a multiyear project to replace it and surrounding roadways, ensuring safe and efficient transportation for generations to come.

The job fell first to Horrocks Engineers, which has 15 offices throughout the western United States, including three in Idaho. Collecting survey data for the bridge and surrounding roadways was a standard job for their mobile mapping unit, said Lonnie Olson, principal and survey manager at Horrocks, but the project also called for bathymetric data for the river bottom and bridge substructure.

“They wanted a look at the scour around the bridge pilings,” Olson said. “One of the avenues they’re looking at is to keep the substructure and much of the bridge itself.”

He knew that adding multibeam sonar data to the mobile mapping cloud data would give the resulting topo consistent, fine-grained, accurate data from the river bottom on up, but there was a problem: Horrocks doesn’t have a multibeam sonar unit.

“In Utah, we don’t have any big rivers, and most of the lakes don’t require much bathymetric data,” Olson said. “We normally just do single-beam sonar, which isn’t what we were looking for here.”

Luckily, Spicer Group has a multibeam unit for just this kind of bridge-scour analysis and hydraulic modeling. Even better, Spicer’s sonar vessel is also fitted with a Leica Pegasus:Two mobile sensor platform for its above- and below-waterline mobile mapping, the same mobile scanning platform Horrocks invested in 18 months prior for its roadway mapping.

Olson decided to reach out to Spicer project surveyor Nathan Shepherd and combine forces on the job—the first time he’d ever subcontracted out to another surveying team.

Done in a Day

Horrocks would drive the bridge and surrounding roadways. Spicer would drive the river to get everything below waterline, the river banks, and the underside of the bridge. Then they’d stitch the data together, extracting the planometrics to create a surface model and topographic survey.

Because the Pegasus is a sensor platform capable of ingesting data from multiple sources, the multibeam and lidar information could be integrated into a single point cloud.

First, Spicer had to drive the 18-foot flat-bottom boat, fitted with a 60-hp outboard, 35 hours to Lewiston from Saginaw, Michigan.

“The mount for the Pegasus is bolted to the boat,” Shepherd said, “and that’s the third iteration we’ve tried so that it was in the right location and not in the way of the guys when they were driving. The multibeam on the bottom, that’s the fourth or fifth generation of mounting to get it just right. You can’t just go out and rent a boat and make it work.”

And while Spicer did, indeed, end up scanning both the river bottom and underside of the bridge at the same time, it doesn’t actually make sense to run both units simultaneously on most projects.

“That always sounds great for marketing,” laughed Shepherd, “but the multibeam doesn’t collect nearly the same amount of data that lidar does.”

While the Pegasus’ lidar unit could grab everything with just a single pass back and forth under the bridge and along the river banks, the multibeam is a bit more like mowing the lawn, Shepherd explained. The team needed 40 or 50 passes with the multibeam to get the bottom of the river and the data necessary for all the clearance elevations and hydraulic study.

Still, it was all done in a day.

All told, it took about three days to set up the full control network for the job, then four days onsite preparing and doing the actual scanning, for a total of seven days in the field— significant time savings compared to traditional methods.

“Ten years ago,” said Olson, “you would have had to cross-section every 50 feet with a robotic total station and shoot in some key points of the structure, and you’d have to spend probably three to four weeks onsite doing control and collection.”

As for the underwater work, “you’d probably have a cross-section every 250 feet, maybe a dozen total measurements with single-beam sonar, and then a model from that,” said Shepherd. “And they wouldn’t have been able to get the scour. There would be no way to know about that. They would have had to send divers down to visually look at it.

So, it’s about one-third of the time,” Shepherd summarized, “and I don’t know how many hundreds of times more data.”

Even better? “When I pulled it all together,” said Olson, “our clouds lined up with a less-than-centimeter accuracy between Spicer’s and our upper and lower data. You would never find that kind of accuracy any other way. You could achieve it, but the cost would be exponential.”

The team completed the data collection in 1/3 of the time compared to traditional approaches, with higher accuracy and significantly more data.

Mobile Mapping’s Back-office Effect

You’ve probably heard the horror stories: “Mobile mapping creates so much data it’s impossible to manage!” “Who needs a survey team when all you have to do is drive a scanner around?”

Of course, it’s true that moving into mobile mapping is going to require back-office adjustments, but they should be relatively manageable if you prepare for them and offer training to your workforce.

Horrocks Engineers has been doing laser scanning for roughly eight years but just moved into mobile scanning about 18 months ago with the purchase of the Leica Pegasus: Two platforms from Leica Geosystems, part of Hexagon. Horrocks’ principal and survey manager Lonnie Olson said it absolutely affected his workforce.

“Some of our field crews transitioned indoors,” he said. “And I have a team of former high-ranging CAD techs that we’ve trained to do survey work. We’ve been able to do most of the post-processing work in-house.”

They also recruited recent graduates from local geomatics programs and started training them as soon as they were on board to work with mobile point-cloud data.

“Now we have a team of five people,” Olson said, “who do nothing but extract data from point clouds all day, every day.”

Leica Geosystems’ Jason Ellis said Horrocks’ experience is typical, and the movement of field staff into the back office should be seen as a smart move and not a conciliation.

“The continuity from the field to the office is always a challenge,” Ellis said. “It’s hard to convey what’s been done in the field and how it needs to be processed.”

By having experienced field staff cross-trained into experts at working with the data, you have people who can intuit what the field staffers were trying to accomplish as they sort out the important data.

Similarly, said Ellis, it can be hugely helpful to have the people who are out in the field operating the scanners also able to work the software.

“I see a lot of people doing post-processing in the field so they know they’re good and can pack everything up or know they need to rescan if they’ve had an issue,” he said. “A lot of field people are starting to take on the role of analysis, and that’s a good thing. You’ve got sharper people in the field who can be that much more productive.”

Cross-training also helps fill the labor gap in the geospatial profession. “It’s hard to find good people, so if the team doing the collection in the field can manage the majority of the post-processing and get to the point where it can be certified, that helps keep projects on track,” Ellis said.

Cross-training field staff to work with point-cloud data increases efficiency and productivity.

As for the tech, Olson said there’s no need to stress about that. Just make sure you’ve got a lot of multi-terabyte USB drives, which are now extremely inexpensive, and don’t go cheap on your hardware.

“Your standard CAD machine handles this stuff just fine,” Olson said. “The software is starting to catch up now. You don’t really need much to get going. It’s pretty simple. Even your basic laptop can handle it. Sure, you need a decent computer, but we’re an engineering firm, so we had them anyway.”

A Seamless Workflow

With all the post-processing done in Pegasus Manager, the workflow was straightforward for combining the datasets. Teams running both vehicles were able to check the data and imagery in real time for coverage, then use the trajectory adjustment module to bring all the data together and constrain for survey control. The Pegasus software uses automated feature extraction and other automated functions to make post-processing fast and efficient.

From there, Horrocks was able to deliver the MicroStation and TopoDOT files to the Idaho DoT. (The software exports to all common industry standard formats.)

“To crunch all that data, it was about a week and a half for a team of four people to extract the full survey,” said Olson. “It’s a lot faster than it was a few years ago.”

Leica Geosystems’ Jason Ellis provided technical support on the job, as he’s been doing for survey teams for decades. Even he was impressed by the speed of collection in this case.

“If I think back to learning field surveying with a transit and steel tape,” he said, “just the amount of time you’d use on small sites picking everything up—to go from that to collecting a mile of roadway data and the underside of a bridge in less than three hours total field time is just staggering. I’ll never get over the amount of data you can collect in such a short amount of time, and how accurate it is. It’s amazing.”

Partnering for Mobile Mapping Success

Even if you’re a relatively large firm, it’s almost impossible to have the right people and equipment in every location. Sometimes partnering with another organization is simply the only way to get the job done correctly and on time.

But how do you know if a potential partner is a good fit? How can you lay the groundwork to make sure things run smoothly and efficiently?

Horrocks Engineers’ Lonnie Olson and Spicer Group’s Nathan Shepherd reflected on what made their recent team-up on this mobile scanning job for the Idaho DoT so successful.

Complementary Expertise

“Being the prime,” said Olson, “I just recommend doing the research. I wasn’t looking for the cheapest guy. I looked into the jobs they’d done and then talked to Leica Geosystems about their experience.”

In Spicer’s case, Shepherd was able to provide a case study showing an almost identical job of scanning a bridge from river bottom to bridge top, which made Olson comfortable from the start.

Plus, they spoke on the phone, and Olson made sure they spoke the same language.

“You can tell when a surveyor knows what he’s talking about,” Olson said. “For this type of survey, if someone said, ‘Can you do a boundary?,’ I’d say I wasn’t interested. Once you throw out a couple of keywords, you know whether it will be an easy company to work with.”

Shepherd said it was also important that both firms had a long history working with departments of transportation. For example, DoTs tend to have very stringent control guidelines, with control set at a certain increment and a requirement for validation points that can be used after the data has been constrained to the control.

“Having both teams experienced in what they’re doing,” said Shepherd, “we both understood what the expectations of the DoT were; we know the end product. We did zero vectorization, just the point cloud, but we know how to collect the data because we know what they need in the end game to deliver.

“A potential partner might have experience with scanning, but if it’s not for the type of client, you might have a tough time articulating why things need to be done a certain way. Both of us having a strong background in DoT work was definitely beneficial.”

A strong background in DoT work helped ensure that both Horrocks Engineers and Spicer Group clearly understood the expectations.

Strong Expectation Management

“Lonnie was pretty good at articulating what he needed,” said Shepherd. “And we had just done a nearly identical job, so we were able to tip him off on some of the issues that we had encountered.”

A project kick-off meeting with all of the stakeholders from both sides can set everything up for success. “Make sure you scope the job fully ahead of time,” said Shepherd.

“Make sure both sides understand what’s needed for deliverables and the scope of the work as a whole so there are no surprises. Well, fewer surprises anyway.”

Communication And Adjusting

Sometimes, unexpected things just come up: In scanning on the Clearwater River, the Spicer team set control with the water level much lower than it ended up being when they did their scanning, leaving their targets submerged and invisible to the above-waterline scanner. However, given strong communication ahead of time and relatively smooth operations otherwise, they were able to tie the data in conventionally without too much headache.

But that’s one lesson learned for the future, laughed Shepherd: “Make sure you know what the normal water level is before you place your targets!”