Above is the object lens for the FOCUS 35, one the largest for robotic total stations with the prism directly attached; this differs from the legacy prism stems that can reduce returned signals. Photos: G. Schrock, from a recent tour of the Spectra factory in Shanghai.

Multiple, distinguished legacy companies in precision optics and manufacturing converged to develop a popular mid- to high-range total station that has earned a strong reputation.

Detailed articles about the development and manufacture of surveying instruments continue to be among the most popular content we publish at xyHt magazine.

And, frankly, I find it one of the most interesting aspects to research and write about. Folks gain more confidence in their gear if they know how it ticks, how it is made, and who makes it.

Surveyors use some of the most advanced instruments of any field profession, often the fruits of distinguished scientific and industrial roots. These instruments represent substantial investments, not only for the individual practitioners, but also for the entities that research, design, and manufacture them. The more a user knows about the origins of the gear, the more confident they feel in the quality.

We have examined many optical and GNSS equipment sources and hear from different user constituencies asking when we will examine their particular “go-to” gear.

One persistent group is the users of the Spectra FOCUS product line (currently the FOCUS 35 total station). Instead of a straight-up product review, we’re looking at the backstory, technology, and manufacture of these instruments.

Over the past few years we’ve done this for other gear, like, “The Power of Light” (Nikon, September 2018), “A Fine Line” (Topcon, August 2018), plus Leica Geosystems, Hemisphere, etc.

Delving into the FOCUS turned into an adventure. This gear is an amalgam of components from a group of companies with a common core, a group of design and manufacturing teams and facilities with interlocking histories.

Our examination culminated with a recent visit to the final stop in the manufacturing process for the FOCUS 35—Shanghai. The factory is as modern and exacting as any we have visited, but it also showcases futuristic elements and innovation that we haven’t yet seen elsewhere. It became apparent that the design and component choices for this system were deliberately aligned to fit a specific value proposition for end users: a mix of the precise, the appropriate, and the affordable.

A unique testing station called the HACS automates important collimation steps. In the tests, most critical parts of the instrument are exercised, from tilt sensors, to drive servos, to the focusing system

A Lens on History

2016 marked the bicentennial of the birth of Carl Zeiss, inventor and industrialist who is widely recognized as the father of the precision optics industry. Originally from Weimar, Germany, he formed a company to manufacture microscopes in Jena, Germany in 1846. The first of the historical technological waves his company (and its legacies) would serve was the mid-19th century boom in biosciences. Higher-quality microscopes for emerging biosciences were in strong demand at the time, and the precision- and quality-focused (perhaps obsessed) Carl Zeiss soon filled this need.

Then, the design and manufacture of precision optics were so much more difficult, as key fundamentals of image science had yet to be resolved and much of the design had to come from empirical data. Zeiss reputedly would personally destroy any instrument that did not meet his standards.

The name and reputation spread globally. But it took 20 years to produce the first 1,000 microscopes. Zeiss turned to a young Dr. Ernst Abbe to grow a scientific staff, expand the product lines, and increase the industrial capacity of the company.

The company expanded to industrial metrology, camera and cinematics lenses, eyeglasses, weapons’ scopes, spectrometry, ophthalmic optics—just about any field of precision optics there is—and of course, surveying instruments. The first Zeiss level instrument, Nivellier 1, based on serial production, was developed in 1908 by the Swiss surveyor Heinrich Wild who founded WILD Heerbrugg many years later in 1921.

Like so many surveyors, I can remember beloved Zeiss levels, pioneering Elta total stations, and seeing the word “Zeiss” printed along the rim of instrument lenses. Zeiss became a global operation by the late 19th century but closed many of its overseas operations at the onset of the First World War. It would regain some of its global reputation and market share post war.

On the other side of the globe, in 1917 two optical companies in Japan merged to form what would become Nikon, one of several precision manufacturers destined to find a connection with Zeiss.

After the Second World War the company reformed in East and West Germany. Much of the historic and ornate 19th-century Zeiss factory in Jena (in Eastern Germany) gave way to newer facilities with a much more industrial look. Part of the present facilities in Jena is a massive, four-floor factory where each floor is double-height. Despite geopolitical upheavals, steady development continued, with Zeiss’ name and reputation attached to a wide range of products.

At the same time, in 1947 in Sweden, scientist Erik Bergstrand had working prototypes of what would become the modern EDM. Bergstrand’s work became part of the legacy of AGA, Geodimeter, and Geotronics. Also, at that time, Nikon began production of early commercial models of its signature line of lightweight, high-precision surveying instruments. These companies were destined to converge paths.

Post-Cold War, the Zeiss Jena facility enjoyed a steady rise in its profile. (Present-day visitors are often amused by visible Cold War reminders, including remnants of painted political murals and a “paternoster”—a continuous, door-less elevator.) Yet, the R&D center and factory are very high-tech.

Though not yet connected, these companies had achieved several notable firsts: the first auto level, commercial laser level and rotating lasers (from LaserPlane/Spectra Physics in Ohio), electronically leveled pipe, and rotating levels. The Spectra Precision division of Spectra Physics would eventually acquire Geotronics (Sweden) and Terrasat (Germany, developer of the first commercially available RTK, and VRS).

Spectra entered a joint venture with Carl Zeiss AG’s surveying business in 1999. The Zeiss surveying business became affiliated with Spectra, that also established working relationships with Nikon in 2003. The combined resources and expertise of the Swedish, German, Japanese, U.S., New Zealand, (and more key locations) would all have a hand in (and provide components for) familiar surveying product lines like the Spectra FOCUS, Nikon Nivo, and more.

By the late 2000s a disruptive shift in global industrial centers was happening in Asia—China specifically. I visited the Shanghai Pilot Free Trade Zone in 2007 and then again, this year; the sheer scale of development and growth hit me with a massive dose of culture shock, and I had to confront my own misconceptions about the state of surveying gear manufactured there. It is in this industrial district of Shanghai that the legacy of Zeiss and these other interconnected companies would implement a rather bold project in 2007—nicknamed “Cupid.”

In August of 2019 I returned to visit Shanghai and tour the production facilities where the FOCUS 35 and other products with optical or leveling component are final assembled. My host was Mr. Gao, a dynamic young fellow who is the production manager.

Gao said upfront that many surveyors might be under the impression that “instruments made in China might be cheap or low quality.” That thinking is outdated. Gao stated that as far as the equipment coming from his production lines is concerned, “Every test is strictly controlled and tracked in the database,” and that testing can be monitored by the engineering teams in Jena based on the Shanghai statistics.

But why move final assembly to China? The obvious answer that comes to mind is labor costs, but even that is not as much of a factor anymore when it comes to high-end instrumentation. The cost of living and wages in industrial centers supporting high-end industries has exploded. There are also factors in play like the material supply chain and larger pools of highly skilled manufacturing technicians and production engineers. Some surveying manufacturers in China produce more of certain instrument types (for domestic markets alone) than several big global names produce—combined. Chinese quality has risen, and with home-grown innovation on the rise.

The labor cost factor is undeniable—though far less of a differential than a decade ago. With the “center of gravity” of high-tech manufacturing trending eastward, there is no surprise that at least some elements of precision equipment for nearly all industries and professions are coming from or being final-assembled there. For example, look at your smart phone. We examine these trends in “Inexpensive Does Not Mean Cheap” (August 2019 xyHt).

Gao is an example: he studied automotive engineering at Tonji University in Shanghai (established by German Physicians in 1907) and worked for Volkswagen (China). His exposure to the German language, and of course to German industrial influences, was a factor in his being offered to join the new Spectra project, Cupid. Gao said the prospect of this international collaboration was appealing and offered new challenges and opportunities.

Engineers in Jena had an idea to develop a new and high-tech production line (for the FOCUS portfolio line of total stations), set it up in Jena to work out all the details, then pack it up and move it to Spectra Shanghai. The first 50 of the then-current model FOCUS were built on the line in Jena. Gao and key engineering, management, and production-line staff were brought to Jena for training on several occasions. And, likewise, teams from Jena were brought to Spectra Shanghai to work together in setting up production.

On the Line

The bottom floor of the Spectra Shanghai facility houses the production lines for several Spectra products and components. The team already had in-house expertise in optical instruments but needed to add new production staff and assemblers.

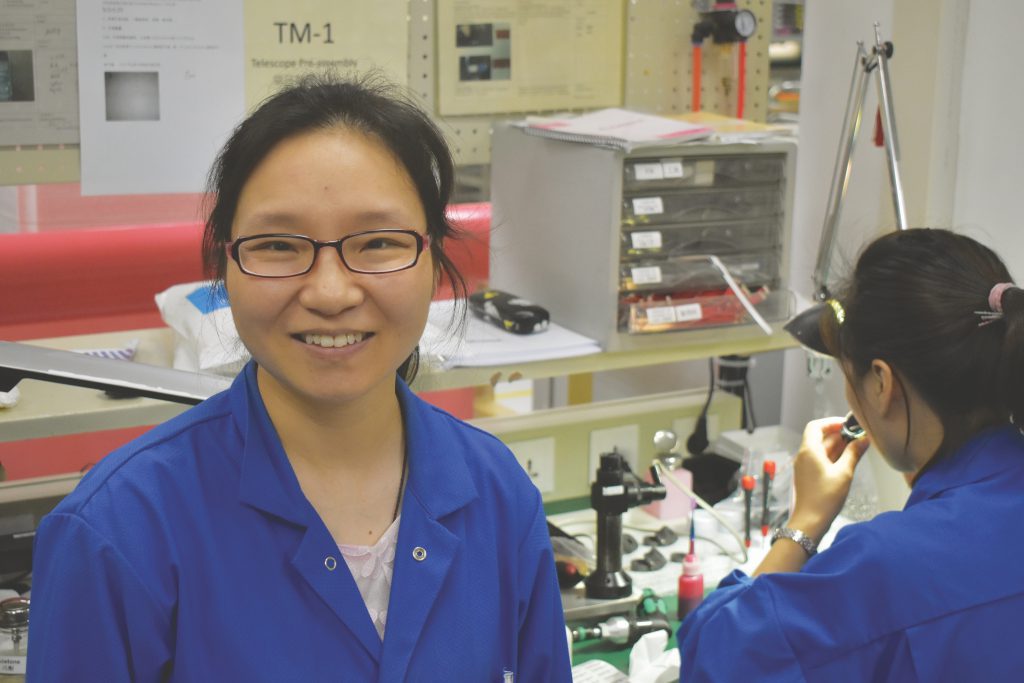

In China there is a massive pool of skilled electronics assemblers, but both Gao and Mr. Wang, head of China operations, said that finding assemblers who can master the art of sophisticated surveying instruments was a very selective process. Wang said that one of the first tasks that a prospective hire must master involves gluing and installing a tiny lens with the aid of a Zeiss microscope (a task I think I would fail to master).

Assemblers are chosen through a rigorous process; one of their first tests involves gluing and installing a tiny lens using a Zeiss microscope.

With Gao interpreting, we spoke with line lead Ms. Shifeng. Shifeng has been with the project since 2010 when the production of what was then the FOCUS 30 was transferred from Jena. Her early career was in electronics assembly. She enjoys working on these complex surveying instruments because it is nothing like the type of manufacturing she had experienced before where one might simply be screwing pieces together. She and her team learn new tasks, rotate positions, and have a direct hand in solving any issues they might encounter. Shifeng also noted that now she finds it interesting when she sees surveyors out working as she has a connection.

Wang says that there is more time spent on testing and quality assurance than on assembling—that is the nature of surveying-instrument manufacturing. He said that not only do they follow strict internal quality steps, but on top of that the engineers in Jena are able to monitor the testing databases and can see records of all steps. Yes, imagine you have a German engineer looking over your shoulder (virtually) at all times; you are going to be sure to get things right.

As I walked through the line of the FOCUS 35, I saw all of the modern instrumentation and test procedures I had seen at other top-end facilities. There are inner workings of total stations (TS) that are not often talked about but are essential and often standard. I saw a unit they call the “grey wedge” that attenuates the strength of the returning beam by varying the angle through a window of materials with increasing opaqueness (i.e. if you are near or far from a target or during tracking searches, sometimes when you get close to the TS you can hear a little stepper motor activating the wedge).

There are the transmit and receive units of the EDM, and the calibration of a return unit is particularly tricky. It takes at least two weeks for an assembler to get up to production speed on this (and most other tasks), and many months to master. Most of the phase-shift lasers used in the respective lines of these combined global operations have a distinguished legacy under the name Venus.

Venus 1, laser class 1, was developed and produced in Jena and was used, for example, in some Elta TS. The updated Venus 2 (in Jena) could be found in a number of TS. In 2007 in the Venus 1, the output power was raised to class 3R for longer range, and a laser pointer was added (for some Nikon series). Various lasers are produced in Jena and Shanghai. Venus 3 EDMs, from Shanghai, are also found in some high-precision TS with an EDM precision of 0.8mm +1ppm.

As one would expect from Jena, Zeiss, and that legacy of optical manufacturing in the mix, attention to the optics is paramount. But one irony further demonstrates that the FOCUS 35, as with just about any high-quality total station (TS), is a global amalgam of components that comes from multiple manufacturing centers and teams working together: you do not see the words “Zeiss Optics” on the rim of the object lens.

The object lens of the FOCUS 35 is one of the largest of any TS. Another feature of the object lens is that the EDM transmitting prism is glued to the back of the lens (in the cover photo of this issue). This is to eliminate the typical stem you see in most TS; those stems can limit the amount of signal return.

The days of a limited number of companies or products from a particular country or world-region having a monopoly on quality are long gone. Amazing resources for quality products and innovation are going on everywhere.

The many elements of automation at Spectra Shanghai surprised me. For example: every total station line has climate chambers, but at Spectra Shanghai, theirs is a large one that runs multiple units, as seen through a large observation window. These are robotically operated, going through temperature cycles, with a reference instrument outside the window.

An automated testing process puts up to eight instruments through temperature cycles overnight for eight hours. Here a reference instrument is set up outside of the chamber.

Four to eight instruments are in the chamber, testing all units in the working range of -20°C to +50°C, overnight for eight hours. I had seen at different facilities where workers had to go into chambers (time-limited for safety) to do tests. There are also shake tables for testing and ovens for components to be heat cycled to relieve structure stresses, but one unique test station truly could take a prize for sheer techie-ness …

The Stone Bot

Some components of the FOCUS 35 are produced at the other global sites. For example, the compensators are produced in Danderyd, Sweden. TS compensators are wonders of technology but must be rigorously calibrated and tested on huge, heavy, typically stone tables. The entire production line at Spectra Shanghai is on the ground floor for stability, and the engineers in Jena developed an additional, unique automated process that uses a stone table with a tall, vertical section added.

The testing process mounted on this L-shaped stone megalith is a guarded process, and I had to agree not to provide many details; as far as I know this is the only one of its kind. It is a solution and a process to automate critical collimation steps.

Each TS is mounted on the horizontal stone table, and the collimation scopes are arrayed on the horizontal and vertical section of stone—which is incredibly stable. This collimator machine replaces someone sighting through the TS eyepiece and enables the TS to be run through an automated cycle. A connected workstation shows the alignment against the reference axis and records all tests.

This stone bot’s real name is the HACS. We asked Mr. Kludas, managing director of Jena GmbH, to describe the unit: “HACS is an automated system used to calibrate the instrument, and record all calibration values for highest accuracy demands and all-embracing quality assurance that remotely can be checked by the Jena engineering team. This HACS machine refers the ISO 17123 and especially the Chinese SIMT JJG standards for total stations and is the key for the first automated production of a full robotic TS in China at all.”

Kludas added, “QA is managed by 100% automated processes; the excellent Spectra Shanghai team is managing these, but also there is a permanent German engineering team in the background.”

Not only does this eliminate potential errors due to operator fatigue or eye strain, but it can also reduce what could be as much as a four-hour manual collimation session to 35 minutes. And, through the calibration process, most critical parts of the instrument are exercised, from tilt sensors, to drive servos, to the focusing system.

Why Do Folks Like Their 35s?

Let’s look at some basics. The FOCUS 35 is a robotic total station with multiple step motor drives (and an audible click for servo lock that some users have said they find is reassuring). It is available in 1″, 2″, 3″, and 5″ and has a track light, a visible laser pointer (uses the EDM beam), and a camera-based passive tracking system (they call it LockNGo technology). The camera also enables a pixel-based offset correction process that averages corrections at a 100+Hz update rate, determining a precision alignment even if the crosshair does not appear to be exactly on target.

There are a lot of other cool features, but I still wondered why users were so loyal to their 35s; it has passive tracking, after all, and there’s a lot of hand wringing among surveyors over passive vs. active. The legacy notoriety of passive tracking is that it might erroneously track some other shiny object (like a sun reflection on a car or window or a surveyor’s vest). There is a trade-off of occasional “oops” with the hassle of having to lug around an active target, another thing to keep charged and operating properly. And there’s a trade-off with the initial expense of purchase, and again if you drop it. There seems to be a whole new wave of passive systems that are greatly improved over legacy systems.

Experience with the gear makes a lot of difference, and there are several tracking modes you can switch among for different situations. For example, there’s a “search everywhere” mode, another mode that keeps the scope moving in the direction you last moved (if it loses you from view), and more.

You can also use the location of the built-in GPS sensor of the data collector on the pole (typically a data collector running Survey Pro) to help tracking.

After learning how to finesse these options and learning to gauge the site for how and when to use features, skilled “35 jockeys” do just fine without the hassles of active tracking. I asked Spectra’s Joe Sass about the feedback from new users taking training sessions, and he said the usual response after one day of use is that a user might still wish for active tracking, but after a few days they find they no longer desire it.

Some users, like surveyor Rich R. in New England, said it was simply a very solid TS and he never really had any tracking issues in his rural work. Others cite the long battery life (the RX model reputedly has the longest battery life among current robotic TS), and the fact that it is among the lightest robotic TS on the market (if not the lightest). Users speak about solid reliability, and these TS have found homes in all regions of the world, from Japan to Africa, UK to Oman, France to the U.S. But mostly I hear that it fits the value proposition: more affordable than high-end “super” TS but with nearly all of the same features.

There is a bit of a fit-for-purpose revolution going on in surveying equipment with some legacy paradigms being challenged. For instance, many users are finding that a powerful field combo is a good-quality GNSS rover paired with a small, light, and high-quality mechanical total station (like some of the Nikons). For those wishing for robotics, units like the FOCUS 35 are quite appealing.

I feel it might be a mistake to characterize the FOCUS 35 as somehow a “lesser” TS than some of the high-end systems. It has some features that others do not and might just be a better fit for certain users—as well as being (mostly) more affordable. Price is not everything, but even if that is a consideration, I saw nothing in the factory tour that indicated anything “lesser” in its manufacture.

On the contrary, I saw quite a legacy, quite an impressive factory, and quite a total station. I can see why users are so loyal to this line.

The author and Mr. Gao visited the bustling Bund district of Shanghai after the factory tour. The scale of development since the last visit has been astounding.