Aerial capture is getting easier and faster, but the subsequent step of CAD linework generation is a bottleneck—especially given the present shortage of qualified drafters. AI is stepping in to help.

In 2017, the co-founders of what would become AirWorks Solutions Inc. first met and began discussing ideas for a new geospatial venture. Both had been successful entrepreneurs, and had combined backgrounds in aviation, aerial mapping, construction, and UAS. The focus turned to the rapid growth in aerial mapping, how to manage the data in a way that could best serve markets like construction and surveying, and where their expertise could have the most impact. The key question was: Where do we see the biggest bottlenecks in this whole process?

A Matter of Recognition

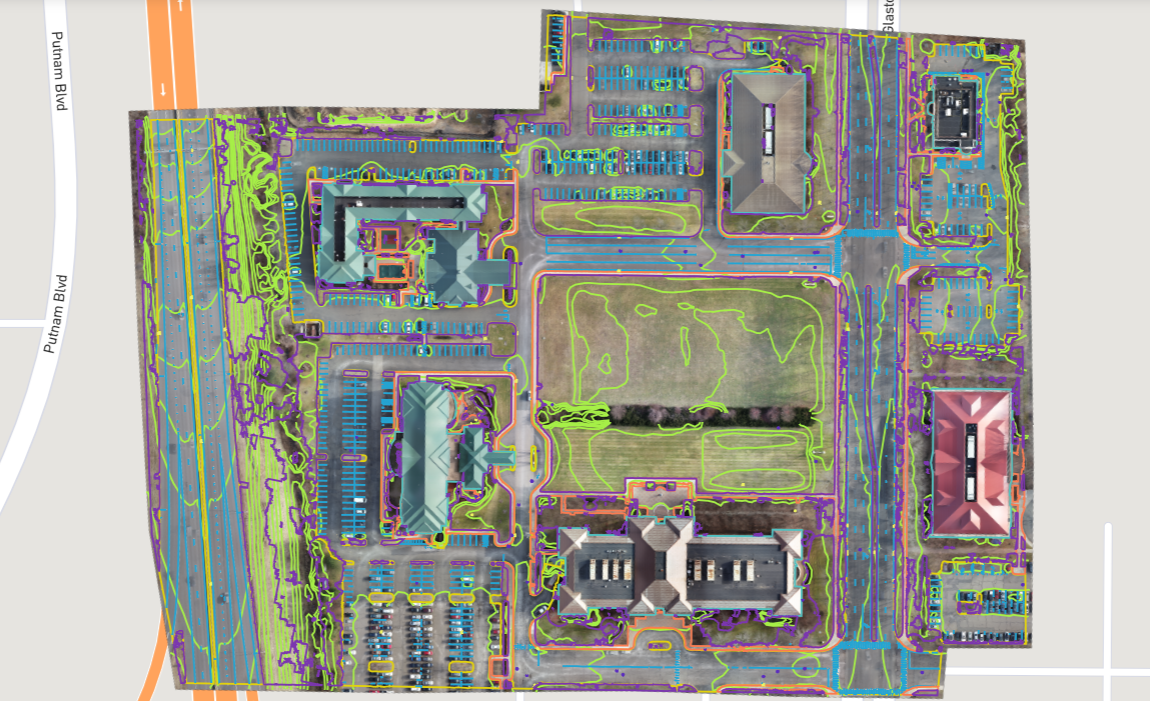

A popular application for this automation service is for surveyors doing assured sitemaps, like ALTA Surveys common in the U.S. Credit: AirWorks

“One of the biggest bottlenecks we recognized was the completion of the CAD files; creating vectors over the raster images and/or from lidar,” says David Morczinek, co-founder and CEO of AirWorks. Morczinek took a look at how self-driving vehicles leverage computer vision to help them with obstacle avoidance. They look at the world as they drive and identify say, a curb, I don’t want the car to drive on the curb or hit a light post, or a person.” Morczinek recognized that for engineering and surveying, there were compatible goals: “They want to know where the edge of road is, back of curb, sidewalk, and buildings, in almost the same way, but in a different form.

Morczinek teamed up with Adam Kersnowski, co-founder and chief evangelist at AirWorks. An early algorithm allowed them to take an ortho image from a drone and extract a building footprint and the edge of a road. That got enough people excited and they raised capital to start the company. They have since gone on to develop a suite of algorithms to extract many more feature classes.

Managing the Data Funnel

Capturing the data—aerial orthophotos and lidar—is now relatively easy and inexpensive. Such technology is no longer just in the hands of large firms and entities. Plus, there are numerous third-party sources for aerial images (and even lidar). The problem then becomes too much data and how to turn it into useable end products like 2D and 3D CAD drawings and models. Throwing more drafting time at the bottleneck can be costly and time consuming. And presently, firms are having trouble finding enough qualified drafters. AirWorks primary goal was to automate the extraction process.

Their flagship product is AirWorks Automate. This extracts to CAD, a high percentage of the expected linework—usually around 85 percent—in the cloud as a service. The remaining linework can be resolved manually by the client or, as most customers chose, have it done by AirWorks. We’ll look deeper into the automation process below.

An as-built with 12 feature classes (plus topography) chosen by a customer for automated CAD extraction from an orthomosaic. Credit: AirWorks

Processing, Precision, and Accuracy

“We run vertical and horizontal assessments with RMSE reports,” says Kersnowski, who has a construction and UAS business background. “The Root Mean Square Error (RMSE) is the standard deviation of the residuals (prediction errors); that is where accuracy is established. We look at it from a quality standpoint. So, when somebody gives us a data set that has half-an-inch per pixel resolution, that is in alignment with survey grade accuracies. That doesn’t mean we can’t process lower resolution data. It’s just not going to be survey grade.” The client can provide ground- check shots to build out an RSME report.

As noted, their online automation step extracts about 85 percent of the desired features, and the customer can then fill in the gap with their own drafters, or as most customers choose, AirWorks uses humans in the loop for QA/QC and to add additional features manually. Clients subscribe to the service, purchase an appropriate number of credits, and upload their data.

“We extract any feature classes. We currently offer 14 classes automatically (with AI),” says Kersnowski. “Other feature classes can be added manually, but we will also further automate that process in the near future.”

CEO David Morczinek (left) and chief evangelist Adam Kersnowski (right) Credit: AirWorks

Prime Applications

Their customer base spans several sectors of AEC. There are as-built surveys of existing sites for design of new structures. Then there are post-construction as-builts. They have customers who are doing design and permits for adding fiber to existing suburbs, others doing impervious surface delineation to compute drainage surcharges, and many more applications.

In the U.S., AirWorks has gained popularity among surveyors who do ALTA surveys. The American Land Title Association (ALTA) is a national trade association representing thousands of title insurance companies, title and settlement agents, independent abstracters, title searchers, and real estate attorneys. A lender may require an ALTA survey, which is a detailed land parcel map, showing all existing improvements, utilities, and significant observations within subject property. The survey also details the licensed surveyor’s findings concerning the property boundaries and how they relate to the title. (See the xyHt three-part series on UAS and ALTA surveys: Part 1: bit.ly/3YZo1cy; Part 2: bit.ly/3Z2ndDK; Part 3: bit.ly/3EixiEs)

Many surveyors have been flying the sites with UAS and doing heads-up drafting for many of the subject features. There will always be some terrestrial survey needed, especially for the boundary elements and other select features, but the efficiency that imaging and lidar brings makes it an attractive addition.

A popular application for this automation service is for surveyors doing assured sitemaps, like ALTA Surveys common in the U.S. This example was an ALTA performed in Glastonbury CT. Source: AirWorks

IaaS

Many potential uses of such a service can leverage “canned” images from image-as-a-service (IaaS) providers. Recently announced by AirWorks is a working relationship with Nearmap, a prominent IaaS provider with web accessible imagery of, for example, more than 1,700 urban areas in the U.S. This includes areas with vertical, oblique, orthometric, and 3D products. Under this working agreement, an AirWorks customer does not need a Nearmap subscription.

Working through the AirWorks portal, the customer creates a project, uploads their own images, and/or selects Nearmap products (where available), specifies which feature classes they want extracted to CAD, and uses AirWorks credits to purchase. Processing typically takes seven days. A typical scenario for users of this combined service would be planning or preliminary engineering alternatives analysis. A truly “shake-and-bake” base map yet based on aerial images of a stated resolution and currency.

If one can get 85 percent of the drafting done at a modest cost per acre, before manual heads-up drafting cleanup, and with a finished product of this quality, I can certainly see why this type of automation service that AirWorks and other vendors provide has generated great appeal.